Professional racing teams have already demonstrated how it would be possible to leverage additive manufacturing to improve performance of cars. As a matter of fact, DAKAR 2021 revealed two more examples with Romain Dumas and ProDrive. However, what I find even more interesting is that the past years saw an increasing number of engineering students explore AM technologies as part of student competitions.

Thanks to the support of AM technologies’ providers, such competitions help those students familiarize with AM technologies. The latest engineering student team that explored new design opportunities for their racing car is Formula Student, a student team from Belgorod State Institute of Technology (Russia).

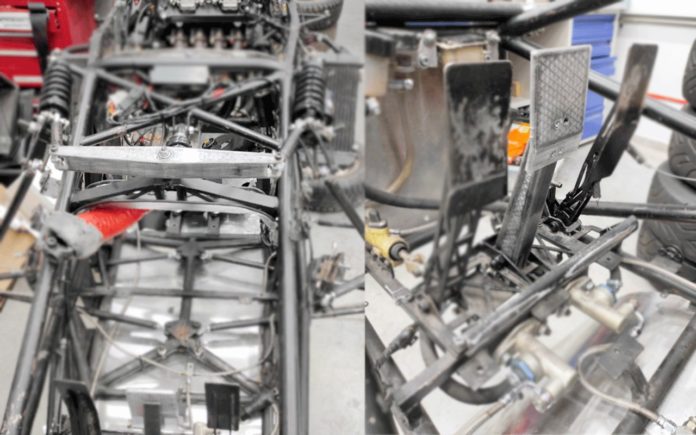

To enhance their car performance, the team has utilized composite 3D printing as a production alternative to metal parts. In this specific case, the automated technology from 3D printer manufacturer Anisoprint has enabled the production of brake pedal and a rocker arm.

The pedal was designed to bear a 4100N load from the brake cylinder. The arm — to redistribute the shock absorber forces of the front suspension system, it takes the maximum calculated load of 1100N.

The machine manufacturer explains in a press communication that the resulting parts were 262% lighter and also saved the manual labour of specialists otherwise doomed to deal with crafting metal parts by themselves. Moreover, there appeared more freedom for the design, as 3D printing allows almost any complex shape at literally no cost while changing the production environment: no dirt, no physically demanding tasks, etc.

In the table below, they carried out a short comparison between that 3D printed pedal perform with Anisoprint’s technology and the characteristics of a metal pedal:

| Anisoprinted pedal | Metal pedal | |

| Cost, EUR | €110 | €20 + cost of labour (6 hours) |

| Weight, grams | 203g | 515g |

| Manual input, hours | 0 | 6 |

| Anisoprinted rocker arm | Metal rocker arm | |

| Cost, EUR | €65 | €15 + cost of labour (7 hours) |

| Weight, grams | 131g | 343g |

| Manual input, hours | 0 | 7 |

“Working hours of the team members are extremely precious, and normally manual labour takes a lot of time. We need inexpensive methods for production automation. We understand that composite materials and additive technologies provide new opportunities: innovative materials, complex shapes, it is important in motorsport“, says Head of the Team Alexandr Pavlenkpo.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com