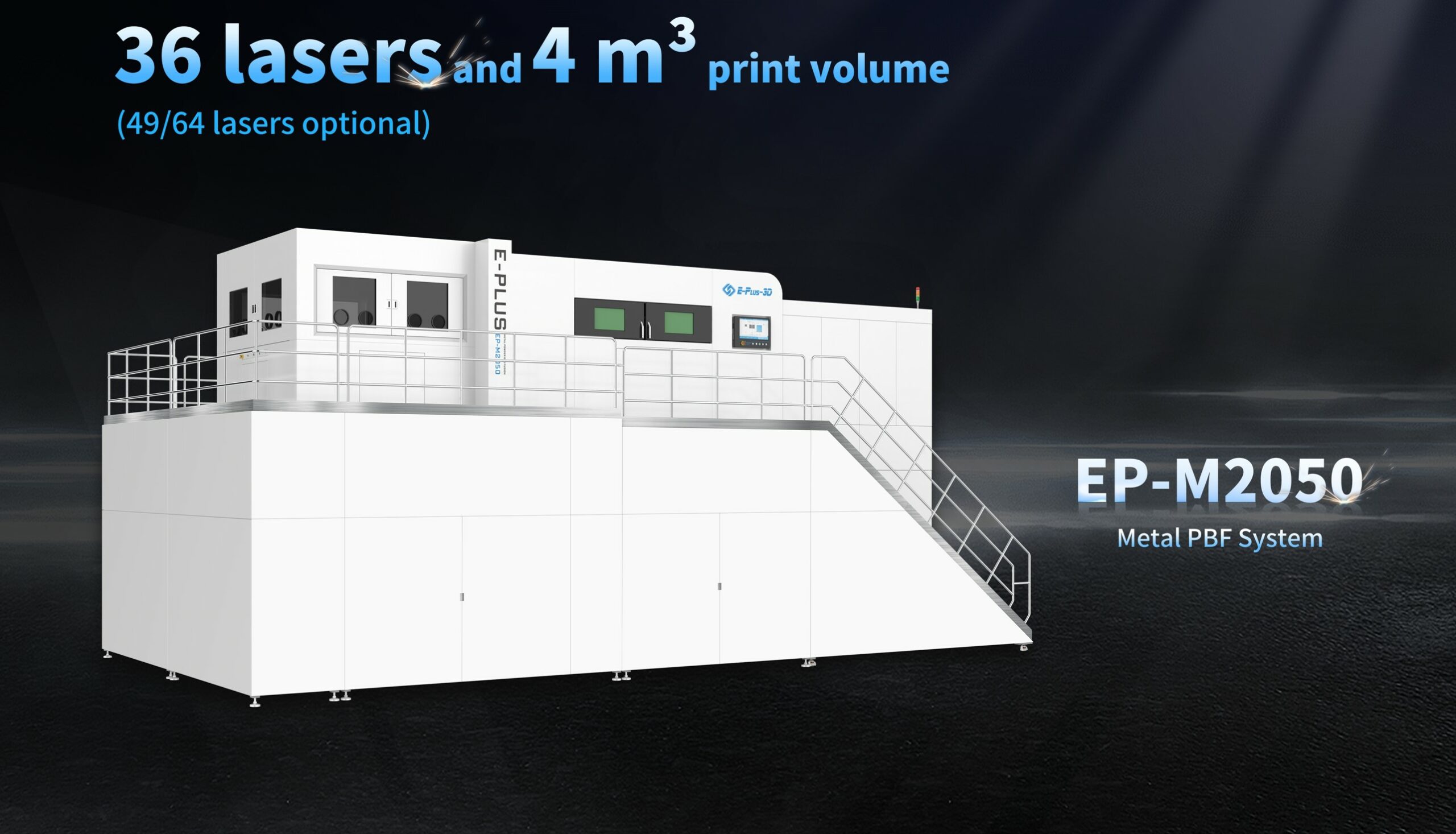

On the heels of the launch of its customizable metal 3D printer EP-M400S, metal 3D printer manufacturer Eplus3D introduces the EP-M2050 industrial 3D printer. Boasting a six-by-six laser matrix equipped with thirty-six galvanometers, this machine would ensure seamless operation of all lasers in perfect synchrony.

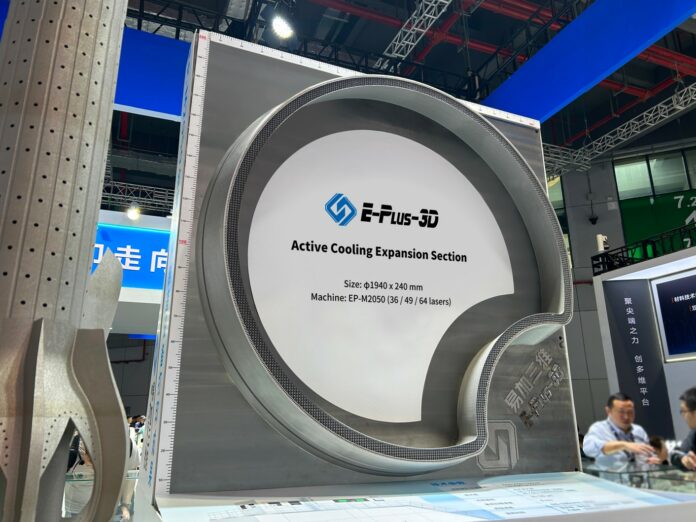

With an optional upgrade to accommodate 64 lasers, EP-M2050 boasts an eight-by-eight laser matrix with sixty-four galvanometers, further elevating its performance. With a build volume of 2050 x 2050 x 1100 mm, extendable to 2000 mm in height, the EP-M2050 3D printer addresses size constraints while maintaining remarkable consistency, catering to a wide range of printing needs, the company explains.

AM users could choose between 500 W or 700 W fiber lasers, thus exploring a diverse range of materials including titanium alloy, aluminum alloy, stainless steel, and tool steel. With a layer thickness range of 20-120 µm, EP-M2050 could manufacture large-scale, high-precision components, making it an interesting production candidate for aerospace and other demanding sectors that prioritize production quality and precision. Same as all of Eplus3D’s large size metal PBF printers, EP-M2050 can be connected to the company’s closed loop sieving tower, ensuring user safety, reduced downtime and waste of material.

Building on the successful launch of EP-M1550 with 16 lasers in 2023 and the successful installation at customer sites, EP-M2050 represents another significant milestone in Eplus3D’s 30 years of experience in Additive Manufacturing.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com