From product manager to Managing Director, it’s been more than two decades that Ismo Mäkelä has been involved at DeskArtes, a Finland-based company that focuses on the development and commercialization of its additive manufacturing software suite.

Mäkelä started his AM career in 1991 as a researcher at Helsinki University of Technology (known today as Aalto University). At that time, their research group developed one of the first rapid prototyping-dedicated software tools of the market, which DeskArtes started commercializing with the name Rapid Tools in 1993.

Over time, DeskArtes has diversified its offering to increase the accessibility of its products within the 3D printing and additive manufacturing industries, and has collaborated with partners such as Z Corporation (purchased by 3D Systems) to develop and commercialize new products.

In this Opinion of the Week, Mäkelä who is also today board member of the Finnish Rapid Prototyping Association, FIRPA – an organization that was founded with the goal to promote Additive Manufacturing information in Finland – shares key insights into the company’s journey, its main products and collaborations as well as its ambitions for the rest of the year.

A few words on DeskArtes and its flagship product

We have discovered DeskArtes as a company that provides a free-of-charge solution for CAD/CAM professionals and hobbyist to check and repair 3D models for error-free production with entry-level 3D printing systems.

Today, the company provides a full set of 3D model preparation tools for professional AM users as well as hobbyists, the ultimate goal being to enable users to run AM systems both for prototyping as well as end-user part production.

Their flagship product, the 3Data Expert 3D data preparation software includes all standard 3D model editing commands. It integrates features such as 3D CAD viewing, dimensioning, STL repair, Boolean, offset, smooth, cutting, hollow etc. As seen in most software of this league, DeskArtes’s solution can convert STEP and native 3D CAD formats to faceted formats for further operations or direct output to 3D Printing.

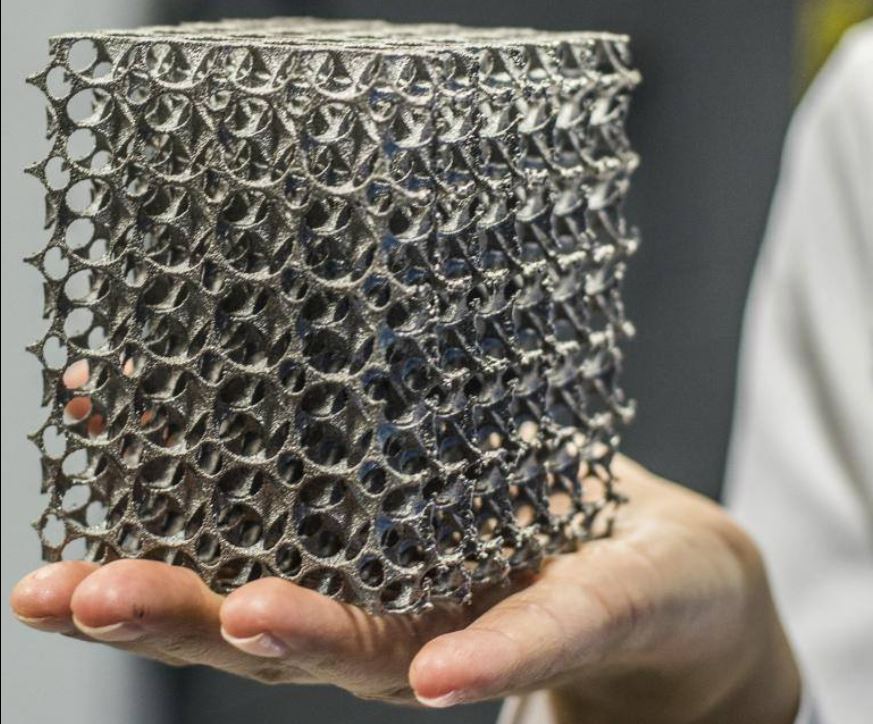

“We provide advanced 3D nesting, 3D lattices, support structure generation, slicing and hatching tools as well as professional PDM reporting tools for manufacturing quality control.

We have also implemented Internet-based cost calculation systems so that users can upload STL files, repair them automatically and get a quote based on the part size and selected material. Even support generation on an Internet server is possible with DeskArtes tools”, Mäkelä explains.

Speaking of the improvements brought to the latest version of the 3D data preparation software (the 3Data Expert version 12.1), the Managing Director outlines: “Version 12.1 was released in June 2020 and it was an incremental step towards professional AM users. New manufacturing reporting functions were added for cost calculation and quality control. Component data from the 3D models prepared with the 3Data Expert software can now be transferred directly into Word or Excel sheets via user-defined templates, enabling connecting to PDM and quality control processes. On the geometry processing side, more efficient slicing, hatching and slice preview functions are now available for quick and accurate part manufacturing. Finally, the support generation functions were improved based on the input from our AM system manufacturer partners and their customers.”

The focus on industrial AM

The Finnish company has been providing manufacturers of industrial end-user parts for a while, mainly through collaborations with AM systems vendors. Mäkelä told 3D ADEPT Media that their Expert Series software packages are made available through standalone licenses or network licenses to users. Each of these packages integrates the main software options required to move from 3D CAD to metal, stereolithography or DLP parts.

The company is currently working with Cubicure GmbH, to convert their “tools to separate library functions and to test them with advanced AM job control system to prepare thousands or tens of thousands of components automatically for 3D printing without operator involvement”.

As the industry cannot advance without collaborations, the manager points out that the key benefit in their collaboration with industrial 3D printer manufacturers is the continuous learning experience their team gets from the users of these systems.

“We are constantly getting new development and improvement ideas from the vendors and their customers. For example, we have been able to optimize our support structure generation software to answer exactly the customer needs”, he adds.

Current challenges manufacturers will address.

The more additive manufacturing advances, the more software requirements evolve. According to DeskArtes’ representative, there are three main challenges where the focus should be made now:

“Firstly, there are probably thousands or tens of thousands of components suitable for AM within stockpile of large manufacturing companies. There will be an increasing need for effective and reliable automatic tools to screen the most suitable components for AM. DeskArtes is already working closely with Finnish company SelectAM to bring these automatic part screening solutions into the market.

Secondly, producing constantly high-quality parts with AM is a continuous challenge, especially with metal AM processes and processes with large shrink factor during the post-processing. Different FEM solutions to simulate and estimate the result and maybe AI-based component positioning solutions should help to improve the quality of the parts. DeskArtes is already looking to develop solutions to these challenges with its university and company partners in different AM areas, like metal and ceramics manufacturing.

Finally, the question of supply chain in general. In the future, significant portions of industrial components should be able to make locally and when needed with AM instead of producing them in large quantities at off-shore factories and by keeping huge stocks of spare parts. How can one effectively control the part delivery, part quality, part manufacturing, AM material flow and access to correct AM systems in the large network of local and off-shore manufactures? That is the key to the successful adoption of AM into the whole manufacturing chain and software plays a major role there.”

Outlooks for this year

From a technical perspective and in the long-run, the Finland-based software company plans to offer 3D data preparation tools for repeatable mass production of AM parts.

Furthermore, in March 2021, they will be releasing a new entry-level module for hobbyists: G-code output for different filament-based systems.

“Hobbyists and DIY builders will therefore have access to better support generation to create parts with improved surface quality and accuracy. The March release will also include new DfAM capabilities for professional AM users, like 3D lattice generation and accurate offsets for 3D models generated with 3D scanning”, the guest completes.

From a business perspective, as every company within this field, DeskArtes always welcomes new partners who want to work on new solutions for the industry. With a key interest in the ever-growing hobbyist and DIY market, DeskArtes would like to provide this niche with high-level tools like advanced support generation and other tools that will help them avoid generating waste material with failed builds.

However, given the Covid-19 world in which we currently live, the first step, according to Mäkelä, should be to let international cooperations do their job of implementing effective vaccination programmes. For the director, if these programmes are well implemented, this would already be this year’s best achievement!

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com