Mumbai-based Bhabha Atomic Research Centre (BARC) recently relied on additive manufacturing for the production of a sample miniature metal part. Miniature metal components play a pivotal role in several critical applications in miniature robotics (bio-robotics), especially in field of customized electroporation devices such as drug delivery, pre-treatment of food, cosmetic therapy of skin, etc.

Given their size and complexities, manufacturing, output management and timely deliveries of these components through conventional manufacturing processes pose several challenges – all of which can be addressed via metal AM.

At the manufacturing level, BARC collaborated with India-based technology company Intech Additive Solutions, a company you may probably have discovered through its software and metal AM solutions. The part was manufactured using Intech Additive’s iFusion LF series of metal 3D printers.

BARC started designing the part using Intech’s AMOptoMet (an alloy parameter development software) & AM Builder and the Intech Design for AM (DfAM) team optimized its using the same tools.

“In my opinion, engineers at Intech have good acumen of technical brilliance, sense of practicality and leadership,” stated Dr Debanik Roy, Scientist, Division of Remote Handling & Robotics, BARC. “I have observed that the engineers follow ‘first principle thinking’, which is very essential for any indigenous out-of-the-box solution for new technology. I am proud to say that within a short span of six months, engineers of Intech have achieved the pinnacle of authentic product-oriented manufacturing with due persistence and passion.”

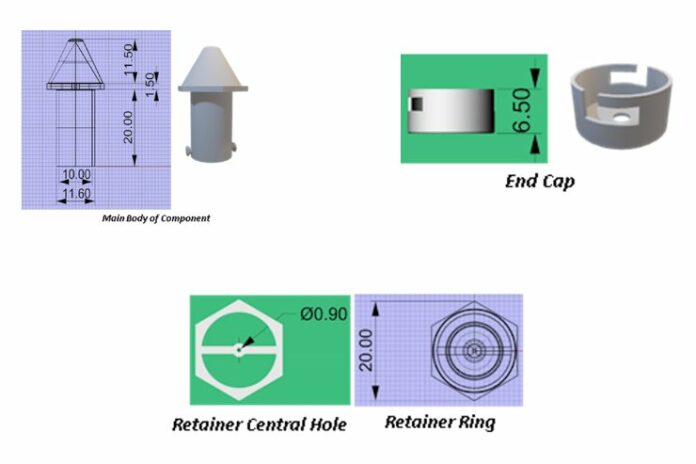

The 3D printed part has a length of 33 mm with a cylindrical housing and tapered front. Central to the build is a ‘retainer ring’, with a thickness of 1.5 mm, incorporating a hole 0.9 mm in diameter. Its ability to function well was crucial to the part’s success. The component was also assembled with an end cover measuring 6.5 mm tall.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com