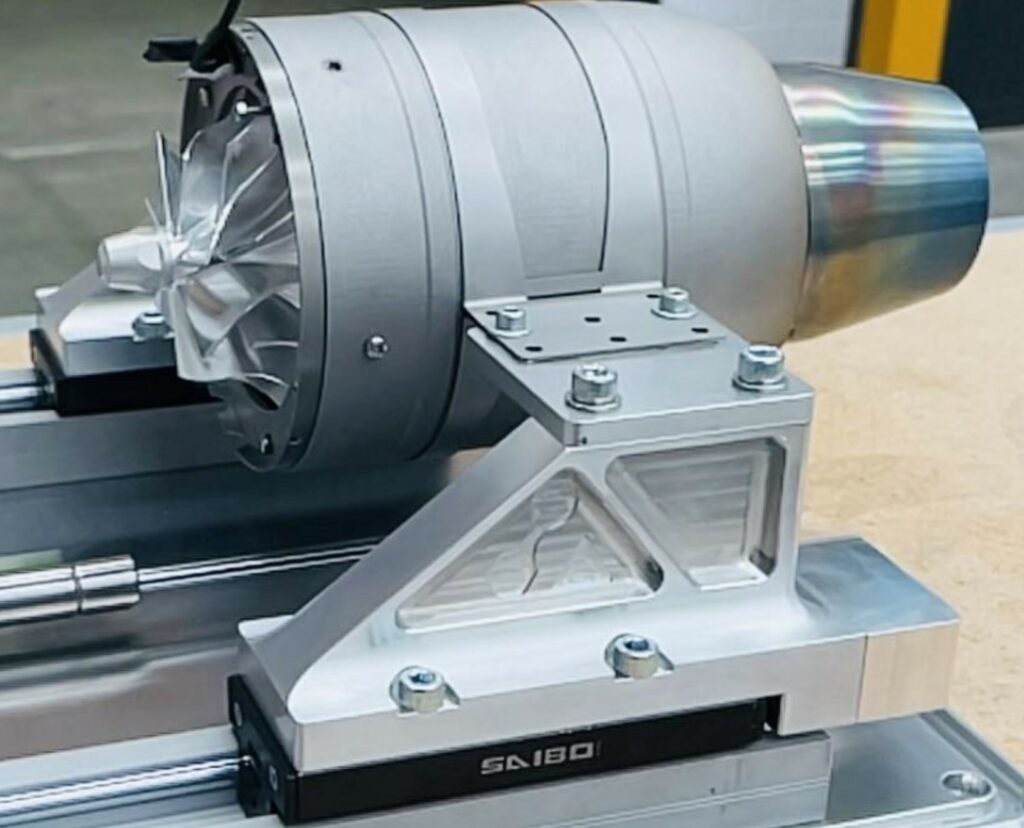

Metal 3D printer manufacturer Aurora Labs is currently fabricating different models of micro gas turbines: the 200N Class gas turbine and the 400N Class model.

A micro gas turbine is a combustion engine at the center of a small propulsion system or power plant that can convert natural gas or other liquid fuels to mechanical energy for requirements in applications including unmanned aerial vehicles or instant power generation.

The current model will be available in the market as early as next month with capabilities for lightweight propulsion systems in a broad range of markets.

As far as the 200N Class gas turbine is concerned, the team has fabricated an advanced product in under 4 months. The turbine engine design and printing have successfully met benchmarks for laboratory prototype testing, which is at the cutting edge of high-energy 3D metal printing of components.

Testing will now move to the field where the engine can be fitted to a remotely piloted airframe.

“We have an excellent level of interest in A3D’s printed engines which also have application not only to unmanned aerial vehicles but also instant power generation. It is our goal to have a cutting-edge piece of technology to sell to the sizeable defence and aerospace markets,” CEO Rebekah Letheby said.

Turbine Development

To develop the prototype turbine engine, A3D has set about meeting market-established benchmarks for its 200N Class turbine engine. The required thrust, air intake efficiencies, engine weight and fuel consumption constraints have been met, and we have further scope for improvement through unique generative design changes, suited for 3D printing.

The engine operates and compares in function and performance requirements to comparable engines built by traditional manufacturing methods. The advantage with the A3D engine is fewer complex parts, that result in a fast and reliable assembly process, without compromising on performance. A3D has the 3D printing machines and expertise to carry out production runs of the engine, onshore in Australia.

Efficiency and the weight of turbines are some of the key areas of A3D’s testing focus. These two items are linked in our turbine model by selecting individual parts which can be lightweighted through design, but also to select metal materials which ensure efficient material performance and allow for a reduction in overall mass. A lighter engine will benefit aircraft with improved fuel efficiency. The design team also focuses to ensure parts of the A3D turbine are amalgamated and printed as one assembly. While this is not possible for all parts currently, the reduction in the current number of parts has ensured time taken to assemble the engine is optimised and the ease of assembly is also improved by using less parts. In one section of the engine, we have managed to take 18 parts and amalgamate that into just 1 printed part, all while realizing a 20% weight reduction on traditional engines of the same class.

The metal materials selected for the 3D-printed parts show the required mechanical strength. Testing has shown that the printed interior components can perform with the required metallurgy withstanding the stress and high temperature that the metal material is subject to during the firing of the engine. The printed material is comparable to conventional metal materials which gives assurance to users that the end quality of the metal product is reliable and repeatable with the A3D printing method.

The next step

In conjunction with testing of the 200N Class model, A3D is fast-tracking the design and build of the larger 400N Class gas turbine model which will further enhance the market opportunities for large-scale applications in the unmanned aerial vehicle sector where small turbines can be utilized as propulsion systems.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com