The last time we talked about AON3D, the Canadian machine manufacturer enhanced its high temperature 3D printer output with duplication mode. Today, the 3D printer manufacturer announces the release of Readyprint™ Filaments that ambition to remove inherent complexities of open material printing without locking down configurability or pricey open material license fees.

The new line is co-branded by Kimya – a brand that you probably know if you’re a regular reader of 3D ADEPT Media and that we have been following from their first days in this industry.

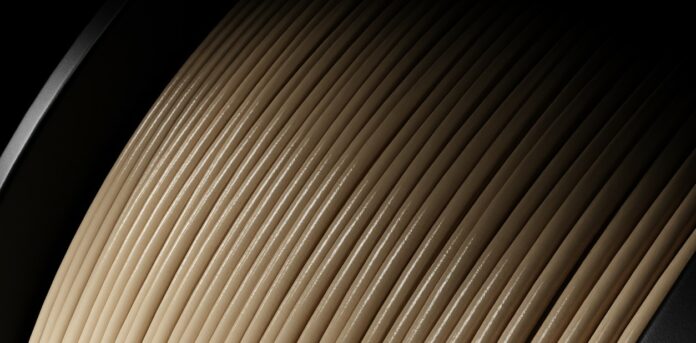

The companies explain in a press release that the materials are sourced from high quality vendors with rigorous quality management processes. They receive additional factory drying and are packaged so that they are ready to print right out of the box. Lastly, pre-configured process parameters provide a jumping-off point that engineers can further optimize for desired properties such as strength, print quality, print speed, lightweighting, minimizing post-processing, and more. To start, Readyprint™ filament options include:

- ABS, ESD ABS, and Carbon Fiber ABS

- ASA

- HIPS

- PC

- PEI 9085

- Amorphous PEKK

- PPSU

- PETG and Carbon Fiber PETG

- 92A TPU

“Our goal is to remove the hassles of sourcing, conditioning, and tuning process parameters to get high-quality results with high performance materials”, Chief Product Officer and AON3D Co-Founder, Kevin Han comments.

We may have already covered AON3D but my multiple conversations with representatives from KIMYA, their experience in producing high-performance materials and the applications they have already demonstrated, make me confident about the promises of this material. I can’t wait to discover its first commercial applications.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com