The print looked perfect — the air didn’t

3D printing has never been more accessible — or more overlooked when it comes to safety. I learned that the hard way, one “perfect” print at a time.

We’ve all seen the rise of desktop FDM and resin 3D printers, bringing fast, affordable prototyping to anyone with an idea. These days, if you can imagine something, you can make it. But one side effect of this rapid adoption is that a technology once confined to factories and labs has now found its way into bedrooms and home offices — often without the proper safety measures.

As a university student printing in a dorm room, I often noticed that faint “melted plastic” smell, even when using the “safest” of plastics like PLA. Like many others, I had stumbled onto one of 3D printing’s least-discussed problems: the particles and gases released during printing.

The safety gap in 3D printing

Research quickly revealed that this smell came from ultrafine particles (UFPs) and volatile organic compounds (VOCs) released into the air — both of which can be harmful if inhaled over time. These emissions are particularly high when printing engineering plastics like ABS. Yet in the maker community, health and safety rarely get the same attention as print speed or surface finish.

Research quickly revealed that this smell came from ultrafine particles (UFPs) and volatile organic compounds (VOCs) released into the air — both of which can be harmful if inhaled over time. These emissions are particularly high when printing engineering plastics like ABS. Yet in the maker community, health and safety rarely get the same attention as print speed or surface finish.

Professional enclosures with proper filtration do exist, but they’re often costly and sometimes lack essential features like real-time air quality monitoring. For hobbyists, students, or small workshops, this means either printing in unhealthy conditions, spending a significant amount, or developing a DIY solution. The only other alternative — constantly exchanging the room’s air — isn’t always practical and can cause uneven conditions that lead to failed prints.

Building Clura — A modular, open-source solution

As an avid maker and aerospace engineering student, I chose the DIY route. Over the past year, I’ve developed Clura, a modular, open-source 3D printer enclosure designed to improve safety, air quality, and usability — without the high price tag.

As an avid maker and aerospace engineering student, I chose the DIY route. Over the past year, I’ve developed Clura, a modular, open-source 3D printer enclosure designed to improve safety, air quality, and usability — without the high price tag.

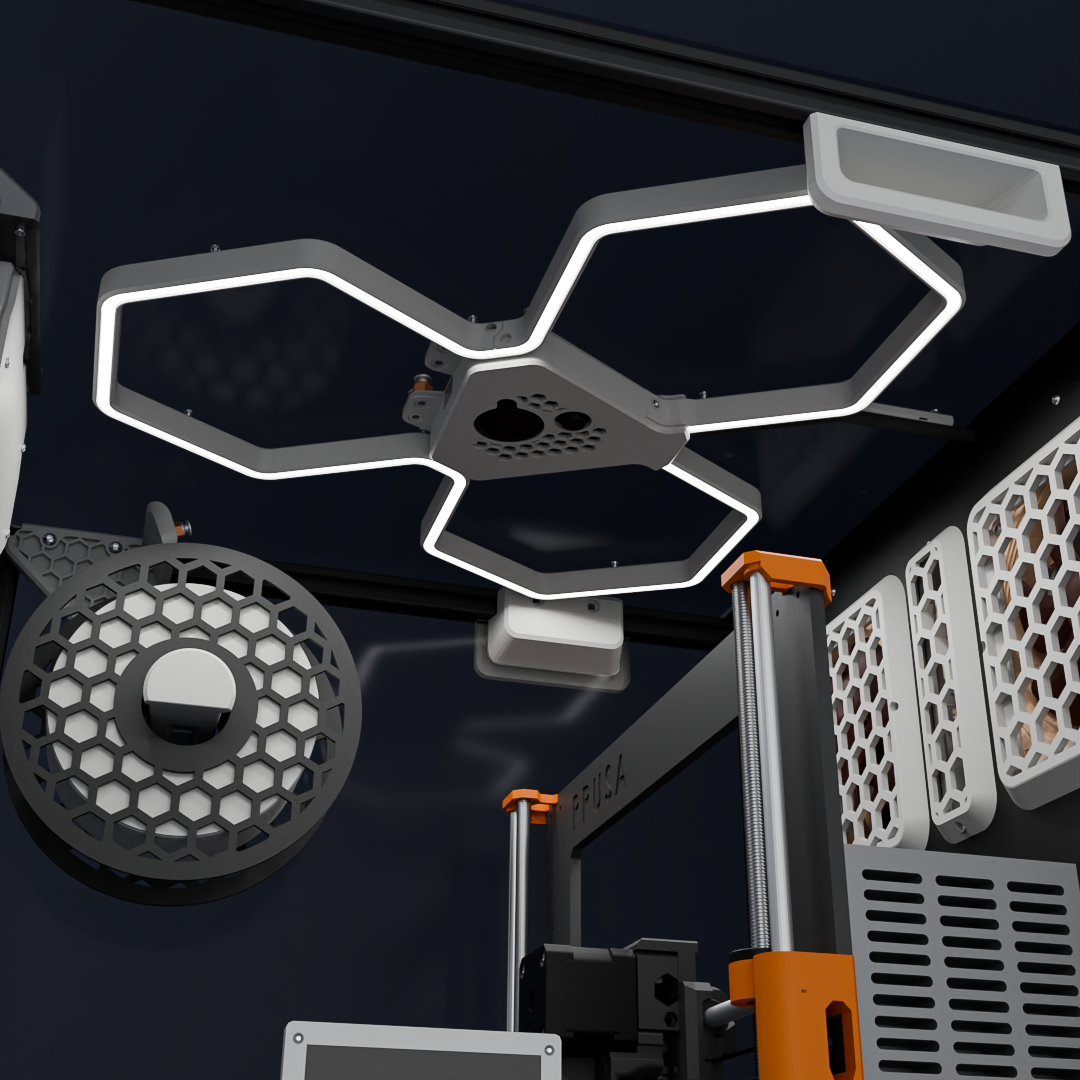

Clura is more than just a box. It includes a HEPA + carbon filtration system that automatically adjusts airflow based on live sensor data, triple-redundant smoke and gas sensors for early fire detection, and load-cell spool holders that track filament weight in real time so you know if a print will finish without a spool change.

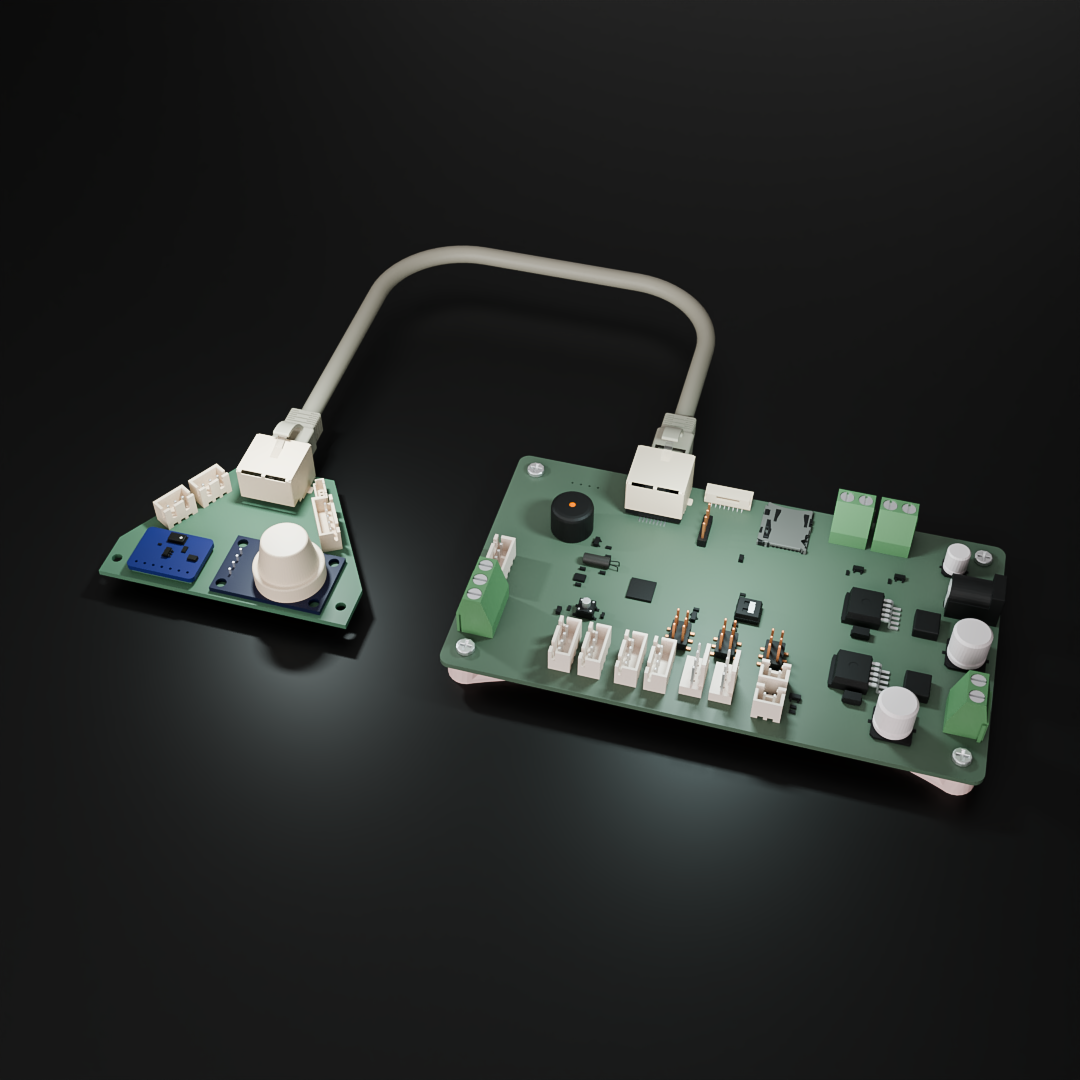

At its core is a custom STM32 PCB driving a sleek 4.3-inch touchscreen interface. The UI logs environmental data to an SD card, provides live readings, controls RGB lighting, and more. The modular frame adapts to different printers and setups, and all design files are available under a CC NC licence for anyone to build or improve.

Why open-source safety matters — And what’s next

Health and safety in 3D printing shouldn’t be a premium feature reserved for high-end enclosed printers — it should be accessible to everyone. By keeping Clura open-source, the design files and assembly guides are freely available for anyone to replicate, adapt, or enhance, making safer printing possible regardless of budget or location.

Health and safety in 3D printing shouldn’t be a premium feature reserved for high-end enclosed printers — it should be accessible to everyone. By keeping Clura open-source, the design files and assembly guides are freely available for anyone to replicate, adapt, or enhance, making safer printing possible regardless of budget or location.

By adopting, sharing, and improving open-source safety solutions, we can protect not just our prints, but also the people making them — ensuring the future of making is as healthy as it is innovative.

This content has been written by Fabrizio Blasio, a maker and aerospace engineering student at TU Delft. Images credit: Fabrizio Blasio.