Formula 1 2020 season officially started on 3rd July with a trip to Austria for practice. For the various engineering and technical teams behind the good functioning of vehicles, it’s also time to go back to work and ensures everything runs well at the mechanical level.

Speaking of that, one that will be able to further bring its expertise in the field is APWORKS. The industrial provider of 3D printing services and products has announced that the alloy Scalmalloy® has been approved by the FIA (Fédération Internationale de l’Automobile). The material is now included in the Formula 1 regulations as one of the additive manufacturing metal materials.

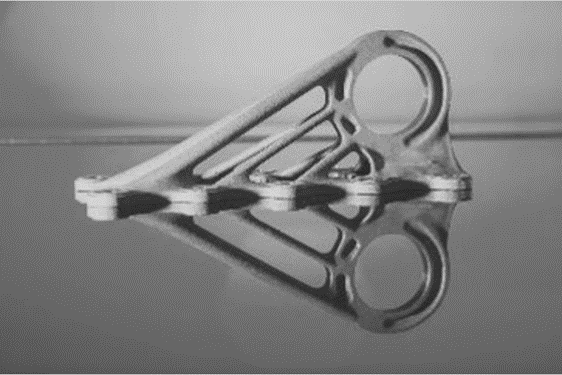

Scalmalloy® is an Aluminum-Magnesium-Scandium alloy which comes with a very high tensile strength (UTS 520 MPa) and yield strength (480 MPa). Its low density provides the metal with specific properties which are above those of other aluminium alloys. Furthermore, Scalmalloy® retains excellent ductility (Elongation 13%). It is corrosion resistant and delivers a high degree of microstructural stability with respect to thermal ageing. High strength and low density enable topology optimized lightweight structural components which can enable better mass distribution to be achieved within the regulation weight limit.

This combination of properties is mainly due to the fact that it has specifically been developed for AM, with design of freedom provided by AM in mind. It therefore exploits the characteristics of the manufacturing process.

Developed by APWORKS in collaboration with its parent company Airbus, Scalmalloy® is suitable for aerospace applications. It is also a good candidate for high-performance applications, especially in the motorsports industry.

“We are proud to see Scalmalloy® in the list of approved materials. Scalmalloy® still stands head and shoulders above all other additively-processable aluminum alloys on the market, and due to its aerospace pedigree, its performance is backed up by all the evidence necessary to give confidence in design. Its extraordinary balance of strength, ductility and density makes it the material of choice in high-performance applications. We are already looking forward to broadening the applications further, as our Motorsport customers gain confidence to apply Scalmalloy® in increasingly critical applications”, says Jonathan Meyer, Chief Product Officer at APWORKS.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com