DIAMANT Polymer GmbH, a company that specializes in polymer systems that protect, improve and increase the durability of 3D printed objects, has developed a solution for sealing components against gas and liquids.

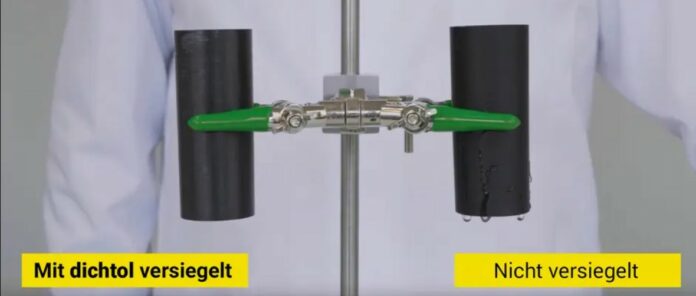

Named dichtol AM Hydro, the low-viscosity high-performance polymer ensures fast and reliable pore-deep sealing and impregnation of the parts. The solution can close pores up to 0.2 mm in diameter reliably leading to porous surfaces that can be impregnated, sealed and finished in a single operation.

Ideal for filament printing and powder-based manufacturing methods, the solvent-free, water-based 1-component system enables long-lasting, gap-free sealing and impregnation of parts and components made of popular materials – especially PLA, ASA, ABS, and polyamide.

Unlike conventional sealers for 3D printed components, dichtol AM Hydro penetrates all pores, no matter how fine, and hardens there. This seals the treated surface and provides it with deep impregnation. Once cured, the hard-elastic polymer anchors itself in the coated part and provides a reliable seal, regardless of changing temperatures. Beyond surface refinement, the polymer system enhances the basic properties of additively manufactured parts, including sensitivity to contamination and geometrical stability.

Create a gas- and liquid-tight seal even in hard-to-reach areas by submerging printed 3D objects in the low-viscosity, high-performance polymer. The application is manual, with no additional machinery or equipment, making it highly adaptable. dichtol AM Hydro is colorless after curing and offers protection for your component. Since the pores are closed, there is no chance for the accumulation of contaminants on the component, and the pigmented parts have great brilliance thanks to the treatment with dichtol AM Hydro.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com