Due to its capacity to dissolve in water — without the use of tools or any type of chemical solvents, Hydrofill is a 3D printer filament that created big hype during its release a year ago. Despite the results brought by this “green solution”, professionals were still limited when they had to achieve certain types of designs. In fact, options were limited when support material, or support structures were needed.

Indeed, according to experts, the simplest technique of exploiting support is to use the same material that is used for the object being printed. That way, “the support is erected similarly to scaffolding on a building and “props up” any steeply angled overhangs. Referred to as “breakable” support, this type of support is effective, but can be messy, time-consuming, and difficult to remove by mechanical breakage or trimming.” One can understand professionals who spend time to clean or cut away support material from a 3D-printed object using razor blades, scalpels, sandpaper, and even power tools.

That’s why the team of Airwolf 3D, 3D printer and filament manufacturer, decided to remedy this situation. “HydroFill is now compatible with a wider range of materials. It’s also less sensitive to moisture and more stable at higher temperatures. What that means is overall improved performance when printing large, complex parts.”

What changed?

The new formula of the filament effectively bonds to more materials. In addition to ABS and PLA, HydroFill can be used with nylons such as 910 Alloy, CARBONITE Nylon. The company is now testing TPU and TPE for full compatibility certification.

Furthermore, thanks to this formula, the filament can be exposed during a longer period to open air.

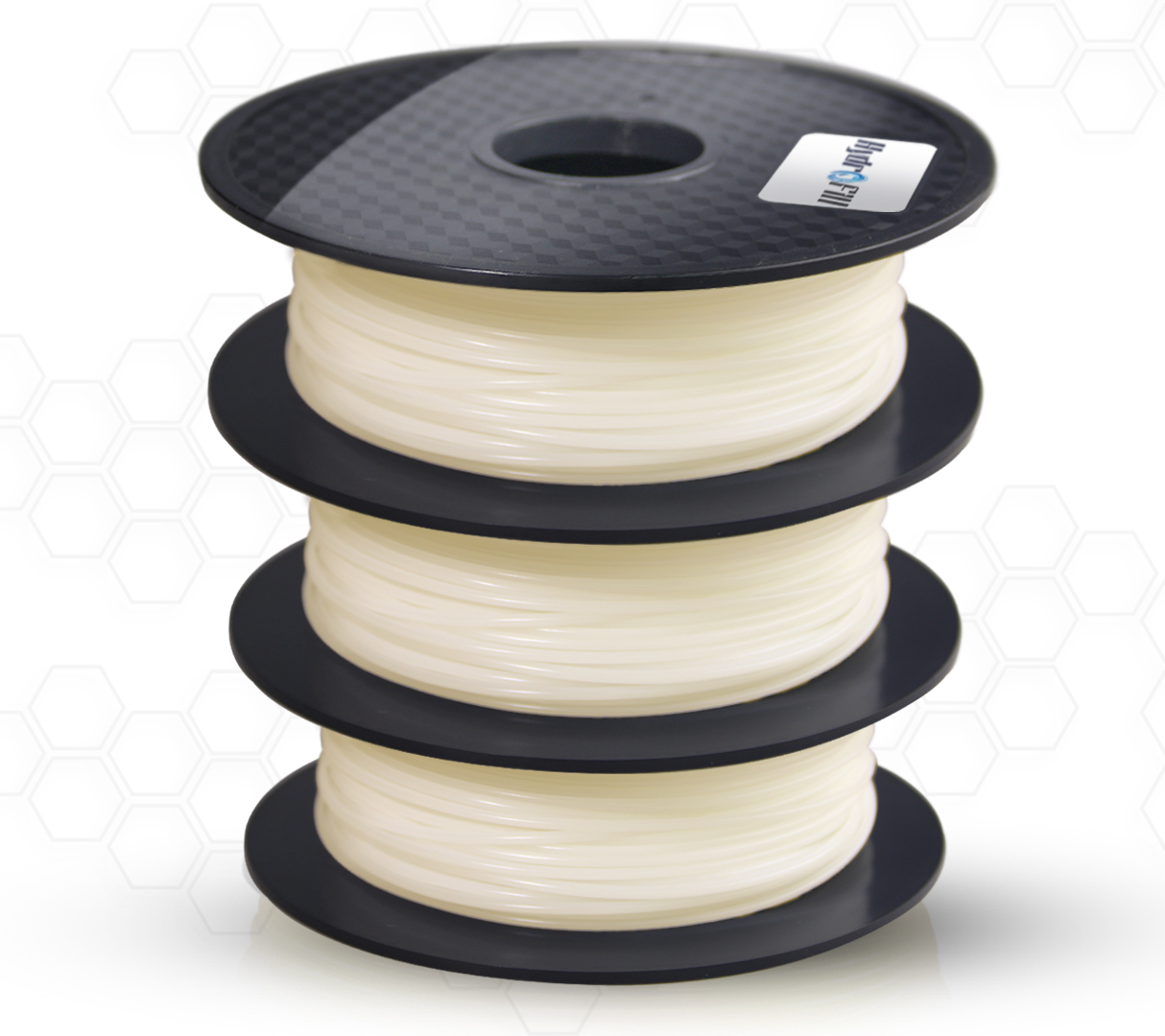

Last, in addition to its original 1-pound weight, HydroFill has been re-released in 2.2- and 5-pound rolls to accommodate extra-intricate or very large projects.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});