As part of a project, Nano Dimension and L3Harris have developed a RF circuit that has been sent to the International Space Station (ISS).

If you are a regular reader of 3D ADEPT Media, then you probably know that Nano Dimension is one of the companies that has made Additively Manufactured Electronics (AME) its core business. L3Harris Technologies – formerly known as Harris Corporation – is a company that provides technology solutions which meet the needs of the air, land, sea, space and cyber sectors.

Both companies have been working together during the past three years on a project that was selected by the ISS U.S. National Laboratory for space effects studies. Three years ago, L3Harris Technologies, together with Nano Dimension, conducted tests to demonstrate viability of 3D printed electronics compared to other manufacturing processes.

In the ISS today, experts will assess the additively manufactured single board for radio frequency (RF) space systems, especially for nanosatellites, and will establish communication with a ground-based satellite tracking system at Embry Riddle Aeronautical University, Daytona Beach, Florida.

The primary purpose of the project is to demonstrate the viability of using new technologies, such as multi-level/multi-material AMEs, which use 3D inkjet printer-based technologies to produce monolithic RF communication systems for use in space.

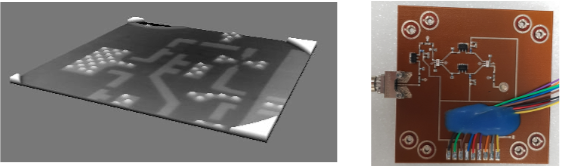

The RF board that has been produced by the Israelite manufacturer includes the antenna, the electronic traces for mounting all the functional components, and the signal ground plane. Prior to the manufacturing process, L3Harris designed the part and made sure it could operate at 2.4Ghz. It also ensured its integration into the MISSE module and launch.

According to the project holders, “this device will be tested at three program points: pre-flight, in-flight, and post-flight. In this space flight experiment, the hardware will fly in the low Earth orbit (LEO) environment for six months on the ISS, which will provide scientists with a better understanding of how AME technology endures in various space environments. Low Earth orbit, a region some 1,200 miles (2,000 km) above the planet, is home to the ISS, as well as a large number of communications satellites, all of which utilize RF communications systems. The possibility of using AME technology for these RF systems had arisen in the past, as it offers several advantages, including the ability to produce low weight, high performance electronic devices, rapid development time, and the ability to fabricate complex shapes and systems that traditional manufacturing cannot.”

While this is the first time Nano Dimension produces RF circuits using 3D printed electronics, it should be noted that it is not the first time RF Circuits have been produced using AM. The latest example has been given by Airbus that achieved a large-scale deployment of radio frequency products using Additive Manufacturing.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com