Data centers face a growing challenge with increasing energy consumption for cooling servers and GPUs.

“Besides the actual IT hardware, the corresponding cooling infrastructure is one of the major energy consumers in a data center – and therefore the greatest potential to improve overall system efficiency,” explains Simon Brudler, 3D-printing specialist and senior consultant at Danish Technological Institute.

At the same time, GPU power consumption has risen from 100–200 watts just a few years ago to several hundred or even kilowatts today, so there is also a need for more efficient cooling.

As part of the AM2PC European research project, Danish Technological Institute and Heatflow, a full thermal solutions provider, develop energy-saving cooling solution that can extend the lifespan of computer chips while enabling the reuse of waste heat.

They were joined by 2 international partners to develop and test the 3D-printed cooling component.

How does it work?

The solution uses passive two-phase cooling and achieved a cooling capacity of 600 watts in tests which is 50 percent more than the original target of 400 watts. In the long term, it could make excess heat usable for district heating.

Paw Mortensen, CEO of Heatflow, who led the AM2PC project, explains that this two-phase solution can remove heat passively without pumps or fans, which significantly reduces the energy consumption for cooling.

The new solution differs from conventional air cooling by using a coolant that evaporates at the hot surface. The vapor naturally rises due to differences in density, condenses elsewhere (where it releases heat), and returns as liquid through gravity.

This passive two-phase process with coolant – a so-called thermosiphon principle – requires no pumps and thus consumes no energy for heat removal. At the same time, evaporation is much more efficient than traditional cooling with air and liquid, so the amount of heat removed from the computer chip is much higher and the chip remains cooler, helping to extend its lifespan.

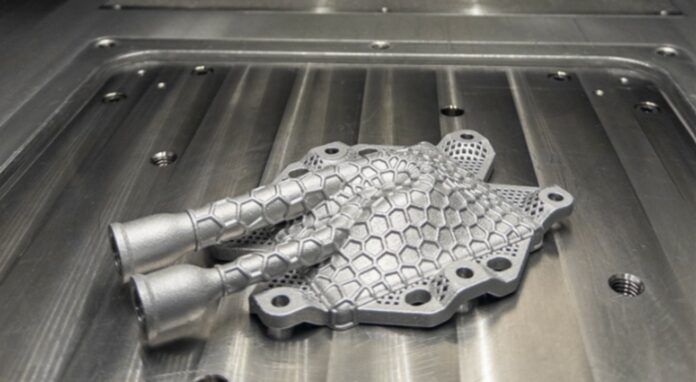

The key component in the system is an evaporator, which Heatflow and Danish Technological Institute have developed and manufactured with 3D printing.

By 3D printing the component in aluminum, they could integrate all necessary functions into a single part. “This eliminates assembly points, reduces the risk of leaks, and makes the component more reliable. At the same time, we use only one material, which makes it easier to recycle,” explains Simon Brudler.

Enabling reuse of excess heat

The project’s focus has been to develop and manufacture the evaporator and validate its performance. This has succeeded beyond all expectations – but a central result of the project is also that the solution removes heat at temperatures between 60 and 80 degrees Celsius.

When heat is extracted at such high temperatures, it can be used directly in the district heating network without additional energy input, but it could also be used for other industrial processes within e.g. food and beverage, textile, paper and pulp, or in agriculture for heating greenhouses – if they are located close to the heat source.

In comparison, traditional air cooling of servers typically removes heat at lower temperatures, making it less suitable for district heating and industrial processes.

“In the project, we did not focus on the integration with district heating itself, but we have demonstrated that the technology enables it. This is an important step toward more energy-efficient data centers that can contribute positively to the overall energy balance”, emphasizes Brudler.

Less material use and better recyclability

Besides the energy savings during operation, the project also shows environmental benefits in manufacturing. By using 3D printing, the overall material usage is reduced compared to conventional solutions that consist of several components made of different materials.

And since the component is produced from a single material, it can be more easily recycled at the end of its lifetime, as there is no need to separate materials.

As this is a demonstration project, it is too early to talk about final environmental benefits, but life cycle analyses indicate that the solution can reduce total emissions by 25–30 percent per unit.

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.