NASA has selected 12 companies to provide launch services for the agency’s Venture-Class Acquisition of Dedicated and Rideshare (VADR) missions. This opportunity will open new doors for science and technology payloads and foster a growing U.S. commercial launch market. Whether they are big or small companies, these space companies all have one thing in common: their utilization of additive manufacturing to produce parts, or sometimes, entire rockets.

The fixed-price indefinite-delivery/indefinite-quantity contracts have a five-year ordering period with a maximum total value of $300 million across all contracts. The acquisition also includes a special on-ramp provision to enable additional providers and incumbents to submit proposals introducing launch services for new capabilities not available or identified at the time of the initial contract award. The VADR contract will provide a broad range of Federal Aviation Administration-licensed commercial launch services capable of delivering payloads ranging from CubeSats to Class D missions to a variety of orbits. These small satellites and Class D payloads tolerate relatively high risk and serve as an ideal platform for technical and architecture innovation, contributing to NASA’s science research and technology development.

“We are incredibly excited to announce the awardees for VADR from a broad range of established and emerging launch providers and launch service aggregators and brokers,” said Bradley Smith, director of launch services at NASA Headquarters in Washington. “This speaks to our expertise in understanding the launch market as we crafted VADR to maximize our efforts in enabling a growing U.S launch industry. With this new tool in our toolbox, these tremendously flexible contracts will meet a wide variety of NASA science and technology needs, further enhancing the agency’s Launch Services Program’s reputation as Earth’s bridge to space.”

What are these space companies?

1. ABL Space Systems of El Segundo, California

The rocket launch company develops a low-costs launch vehicle and launch systems technology using CNC and 3D printing to reduce launch operations. The company currently works on its RS1 rocket, intended to launch as much as 1,350 kilograms (or nearly 1½ tons) of payload to low Earth orbit – at a price of $12 million per launch. This means ABL targets the middle of the commercial launch market as the RS1 is in-between Rocket Lab’s small Electron for $7 million and SpaceX’s heavy Falcon 9 for $62 million. Following a comparison with traditional manufacturing processes, the space company decided to vertically integrate as many parts of RS1′s manufacturing as possible, such as designing the E2 engines to be 3D printed in three pieces, so as to fit in readily available metal 3D printing machines.

2. Astra Space Inc. of Alameda, California

The company is also on a mission to provide a much lower cost to customers to reach orbit. Via a SPAC merger with Holicity, the company became in July 2021 the first space launch company to trade on Nasdaq. Its “Rocket 3″ stands 38 feet tall (1158,24 cm) and with a payload capacity of 331 pounds (150,139). While the company does not always highlight its use of additive manufacturing as a key differentiator, we do know they utilize the technology for those parts where they cannot do otherwise at a lower cost. The Rocket 3.0 for instance, (Astra’s latest launch vehicle) integrates 3D printed impellers for pumps and rocket engine chambers.

3. Blue Origin Florida LLC of Merritt Island, Florida

The developer of rocket engines, launch vehicles, and capsules has also previously worked with NASA as part of a non-profit project that ambitions to give students and teachers the ability to build and fly affordable experiments in space. Educators and engineers have been able to design and test standard equipment for classroom-developed experiments, including 3D-printed frames, customizable processors, power adaptors and more. Thanks to support from NASA’s Flight Opportunities program, the equipment will fly higher than ever before: to space on the next launch of Blue Origin’s New Shepard rocket.

That being said, as far as its manufacturing operations are concerned, it should be noted that Blue Origin’s lunar lander system should integrate an additively manufactured high-performance BE-7 engine, which engineers at Blue Origin had already begun hot-firing.

4. Northrop Grumman Systems Corporation of Chandler, Arizona

Northrop Grumman continuously explore new ways to leverage advanced materials and advanced manufacturing techniques such as AM to solve problems in space, aeronautics, defense and cyberspace. While it often highlights what 3D printing can do in general on its blog, we believe it’s only because of confidentiality reasons that they can’t share much on how their aerospace engineers utilize AM to develop countless options for radiation shields, or fabricate spacecraft components that are precisely customized to withstand the harsh conditions in space.

5. Phantom Space Corporation of Tucson, Arizona

Startup Phantom Space ambitions to become the “Henry Ford” of rockets. With the goal of launching 100 missions a year, the launch space is on the path to achieve this goal thanks to the expertise of their cofounder and CEO Jim Cantrell – The latter was the very first vice president of business development of SpaceX, when Elon Musk founded the company in 2002. Interestingly, with the fluidity and competitiveness of aerospace supply chains, Phantom does not really see the need to invest in the purchase of AM systems. It rather prefers to buy 3D printed parts it wants rather than build everything from scratch. For example, it buys 3D-printed engines from Ursa Major in Colorado. The design of the flight computer was licensed from NASA, and it uses a BeagleBone Black board that some distributors sell for around $50.

6. Relativity Space Inc. of Long Beach, California

Relativty Space is one of the space companies that communicate a lot about its use of AM technologies – which we love obviously. Backed by various technology partners, Terran R, the company’s fully reusable 3D printed rocket, catalyzes Relativity Space’s latest funding round of $650M.

7. Rocket Lab USA Inc. of Long Beach, California

In 2019, Rocket Lab celebrated the completion of its 100th 3D-printed engine since it introduced the Rutherford engine in 2013. In 2020, German metal 3D printer manufacturer SLM Solutions announced it had produced the “world’s largest rocket engine” for the company. If that does not tell you how much these aerospace engineers believe in AM, what would?

Last year, the Founder and CEO Peter Beck rang the Nasdaq opening bell of Rocket Lab via SPAC at valuation of $4.1 billion.

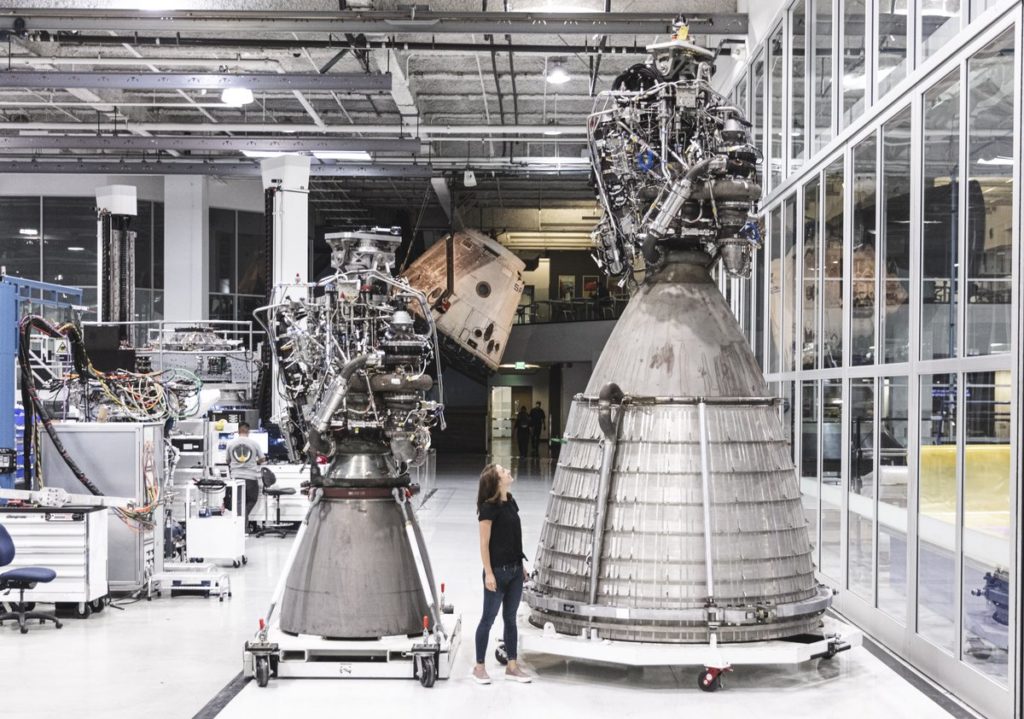

8. Space Exploration Technologies Corp. (SpaceX) of Hawthorne, California

While the company is currently making a real splash with its 3D printed building extension at Texas Starbase – a project conducted by Apis Cor -, the company SpaceX did invest in EOS machines and Velo3D metal 3D printers for rocket production.

9. United Launch Services LLC of Centennial, Colorado

This joint venture of Lockheed Martin and Boeing already has a combined amount of 135 consecutive launches between their Atlas and Delta rocket families. Both spacecraft integrated a range of 3D-printed parts. At present, the company is on a mission to make space more affordable by deploying innovative programs like AM efforts.

10. Virgin Orbit LLC of Long Beach, California

Virgin Orbit first appeared in our radar when NASA Marshall Space Center announced that, together, they should explore multi-metal 3D printing to build multi-metallic combustion chambers. Last year, the company discussed with 3D ADEPT Media its current use of additive manufacturing technologies and some of the challenges the Space industry faces in the adoption of these technologies.

11. Spaceflight Inc. of Seattle

With nearly 400 satellites, ranging from CubeSats to a 700-kilogram satellite, across 40 missions, Seattle-based Spaceflight Inc. delivers a comprehensive range of launch, mission management, and in-space transportation services. It coordinated the launch of more than 20 payloads for NASA over the years and is currently one of only three organizations to launch an orbital transfer vehicle.

12. L2 Solutions LLC of Houston

L2 Solutions delivers tailor-made services, spacecraft design and manufacturing services, enabling its clients to engineer, design, and operate spacecraft. Unlike other companies that often put AM at the forefront of what they do, L2 Solutions on the other hand highlights its expertise with a proprietary technology that combines artificial intelligence and machine learning with human intelligence in order to provide information on events before they happen. Nothing has been shared so far on whether or not they use AM.

NASA’s Launch Services Program at the agency’s Kennedy Space Center in Florida will manage the VADR contracts. The agency works with private industry, mission, and international partners to launch science payloads ranging from small satellites with colleges and universities to NASA’s highest priority missions.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com