What’s interesting about 3D printing is that sometimes, we find applications in fields that we do not expect.

Cincinnati Zoo & Botanical Garden, a zoo that harbours about 2,000 animals, including world-famous hippo Fiona, wanted to mimic natural feeding behaviors in the animals they care for. David Orban, Cincinnati Zoo’s animal excellence manager explains that it’s not always easy for animals to find, acquire, and process food.

“One challenge that we often see when we offer live insects to some of our birds or small mammals is that they are captured and consumed in a matter of five to ten minutes. We’ve had the idea to create a more complex feeder that will extend foraging duration, in turn, extending animals’ physical activity and mental stimulation, leading to more naturally behaving wildlife,” Orban explained.

Orban’s team has therefore been analyzing animals’ behaviour in their environment and with each other. Data they collected help them understand animals’ life at the zoo. Furthermore, the zoo also partnered with GE Additive’s AddWorks consulting team in Cincinnati that used these data to invent a way these animals could easily find their food.

“To kick things off, the Zoo team showed us around and explained their goal to keep animals engaged and enriched. We were thrilled to be working with such an atypical customer and challenge that would allow us to demonstrate that, with additive technology, the sky really is the limit”, said Shannon Jagodinski, lead engineer at GE Additive in Cincinnati.

The creation of a new feeder: challenges and design feasibility

First, it’s never easy to establish communication between two teams that operate in two different fields.

For the GE Additive’s team, it wasn’t easy to communicate with zoologists, it was even harder to open their eyes to the possibilities of 3D printing. Secondly one stringent requirement in the design feeder was to ensure “safety for the animals, keepers, and visitors” on the one hand, on the other hand, to make the enrichment device look natural within the animals’ environment.

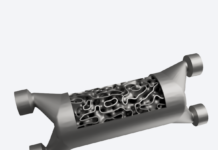

The team at GE Additive therefore developed a device that disconnects the keepers from feeding the animals, disbursing food into habitats at random times. The exterior of the device replicates a tree trunk with a bark-like texture, and the inside of the feeder has a central enclosure to house crickets, which is connected to varying length tubes that exit the device at different points along the exterior.

Depending on which tube the cricket selects, it takes a different amount of time to leave the device, which therefore provides crickets to the animals at varying times.

“After this feeder concept was selected, my initial questions were ‘how big is a cricket and what size tube do they need to crawl through?’ We got some feedback from the Zoo’s insect team and tried three different tube sizes. We printed prototype tubes with three different diameters and tested them in a cricket enclosure at the zoo to see which size worked best,” said Jagodinski.

“We have seen that foraging time and the animals’ investigation and interaction last for up to a few hours in our tests compared to a few minutes, which is really exciting for us because that means we can utilize it multiple times a day and in different habitats. We have really seen that a lot of animals have been interested in it and continue to stay interested in it, which is exactly what we wanted,” said David Orban.

Remember, you can post AM job opportunities for free on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com