A heat exchanger is a device used to transfer heat or thermal energy between two or more fluids or from one medium to another.

Heat exchangers can be explored in a wide range of practical applications. They can be used in cooling and heating processes, refrigeration, fuel cells and the types of internal combustion engines used in cars and aircrafts.

With the goal of enhancing the manufacturing process of these devices, a team of engineers from the University of Glasgow have explored a method which exploits the unique properties of microscale surfaces. The result of this project is a new type of lightweight, 3D printed heat exchanger with a maze-like design. In practice, the new heat exchanger would be more compact and efficient than its conventional counterparts.

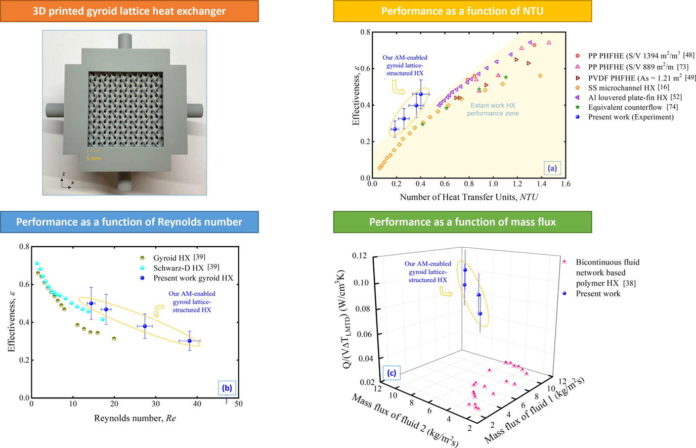

Despite being one-tenth of its size, the newly-developed prototype system would be 50% more effective than a market-leading conventional heat exchanger. The key of this efficiency lies in the design of architected surfaces over which liquids flow through the exchanger. The cube-shaped exchanger draws water through a core studded with tiny holes arranged in a gyroid configuration.

Gyroids are part of a group of cellular designs that are constructed using triply periodic minimal surface geometries having non-self-intersecting and highly symmetrical periodic surfaces.

The team chose to use a repeating gyroid architecture for their heat exchanger because the effectiveness of heat exchange is linked to its surface area – the larger the surface area, the more opportunity the fluids have to pass their thermal energy from one to the other. This means that objects with large surface areas can cool or heat fluids faster than those with more limited surface areas.

Their microscale gyroid design, which they manufactured from a simple photopolymer using a sophisticated 3D printer, engineers a large surface area into a compact cube measuring 32.2mm on each side and weighing just eight grams.

By drawing water through this dense maze, the researchers were able to demonstrate temperature changes of between 10 and 20ºC when water flowed through their heat exchanger at a rate of between 100 and 270 millimetres per minute.

The team measured the heat transfer coefficient of their new exchanger– the measure of its effectiveness in transferring heat between the fluid and its surfaces – so they could determine how it performed against a series of differently-sized conventional heat exchangers made from materials including polymers and metals.

They found that the effectiveness of their new heat exchanger was 50% more than a thermodynamically-equivalent, most-efficient, counter-flow heat exchanger even though their newly-developed prototype was only 10% of its size.

Dr Shanmugam Kumar from the University of Glasgow’s James Watt School of Engineering led this research project. He explained that they have already demonstrated how this type of microarchitected, 3D printed lattices can be used for purposes including recyclable high-performance batteries and the development of future ‘smart’ medical devices like prosthetics and back braces.

“Being able to develop smaller, lighter, more efficient heat exchangers could help us develop refrigeration systems which require less power, for example, or high-performance engines which can be cooled more effectively. We’re keen to develop this technology further with future research”, he said.

The team’s paper, titled ‘High performance, microarchitected, compact heat exchanger enabled by 3D printing’, is published in Applied Thermal Engineering. The research was supported by funding from an Abu Dhabi National Oil Company.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com