Sprybuild, a newcomer in the AM market, turns stealth mode off with the launch of an SLA 3D printer. The machine would integrate a patented continuous build process on a conveyor belt and rigid optical interface – ensuring the quality of each print.

To production users, these advances mean significant reductions in print farm footprint, number of highly-qualified operators and cost of production, the company says – three main hurdles that have been slowing down the adoption of 3D printing.

Key features

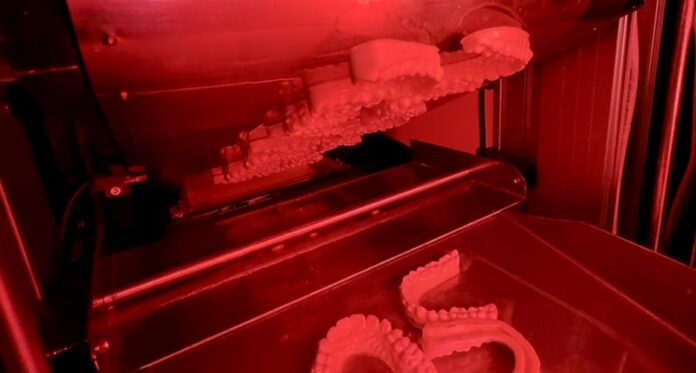

Unlike other resin 3D printers, Sprybuild’s machine comes with a conveyor belt instead of a build platform. This metallic belt moves at a sharp angle to DLP projection and has a remarkably high degree of surface stabilization, achieved through the utilization of an efficient yet simple patented magnetic system. Additionally, it offers an automatic printed parts release feature that virtually eliminates printer downtime, Sprybuild explains.

Moreover, Sprybuild’s technology implements a solid optical interface, enabling a continuous build process similar to, yet distinct from, the CLIP technology developed by Carbon3D. The challenge here was twofold: to eliminate the need for inhibiting resin near the interface and, at the same time, to create “dead zones” where the resin could remain liquid. These zones are crucial for ensuring a steady flow of resin into the printing area, a key factor in achieving high-speed printing. Sprybuild’s ingenuity led to the development of an interface that meets these requirements, ensuring sufficient resin flow and curing only where necessary.

‘‘We pioneered the unique continuous build process that eliminates resin inhibitions with oxygen or light and supports a wide variety of third-party UV resins. In a recent prototype, we achieved quality and stable printing of dental models at a speed of 55 mm/min (100 microns layer), with the potential to reach 150 mm/min. This speed is at least 20 times faster than the average commercial resin 3D printer (~2.5 mm/min) and is truly remarkable!” Sprybuild notes.

In addition to speed that is enhanced, the 3D printer would enable cost reduction through automation and the use of widely available UV resins. Not to mention that automated slicing, nesting, and the post-processing unit would make it easy to address complexity of the printing process.

The SLA 3D printer would be ideal for dental models, shoe soles, and orthopedic insoles, eyeglass frames and fashion accessories, hearing aids, prosthetic components, printed molds, and combustible models for precision casting.

As Sprybuild aims to further develop its technology through pilot projects, it invites partners, investors, and manufacturers to join them in what could be a new chapter for SLA 3D printing.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com