Given the constant comparison between AMF & 3MF, we asked Bob Zollo, President of Avante Technology, LLC, to share his thoughts on how the AMF & 3MF formats should respectively be used. This Q&A series follows a dossier on key 3D printing file formats.

Software companies Avante Technology and Mind in a Box recently developed a free source code for an AMF file converter. Called AMFSample, and now available to the public, this software enables the conversion of STL files into the ISO-compliant AMF format.

- What are the key factors influencing the choice of a file format for 3D printing?

The factors may be different depending on the intended application and industry. For example, STL or OBJ formats may be adequate for simple, lower precision prototypes. These formats are usable royalty-free and are supported by the great majority of software applications and 3D printing systems. Engineers and hobbyists alike are familiar with STL, so there are no economic or IP licensing barriers. Functionality and precision may be limited, but adoption is easy with minimal investment.

Any manufacturer seeking to adopt and leverage true additive manufacturing(“AM”) to make quality parts and assemblies for commercial, medical or military use will consider a broader range of factors, including legal, regulatory, cost of adoption, cost of migrating from historical formats(if any), maintainability, compatibility with software applications and systems used in the manufacturer’s workflow, the expected life of the format’s usefulness for the intended application, and adaptability for planned and future use.

In some industries, namely the medical, aerospace and defense ones, there are regulatory requirements that factor in on the decision. The FDA and EU medical authorities have recently published requirements for the manufacturing of medical devices, that require validation of accuracy, precision and overall quality, as well as verification of these attributes by authorized third-party auditors.

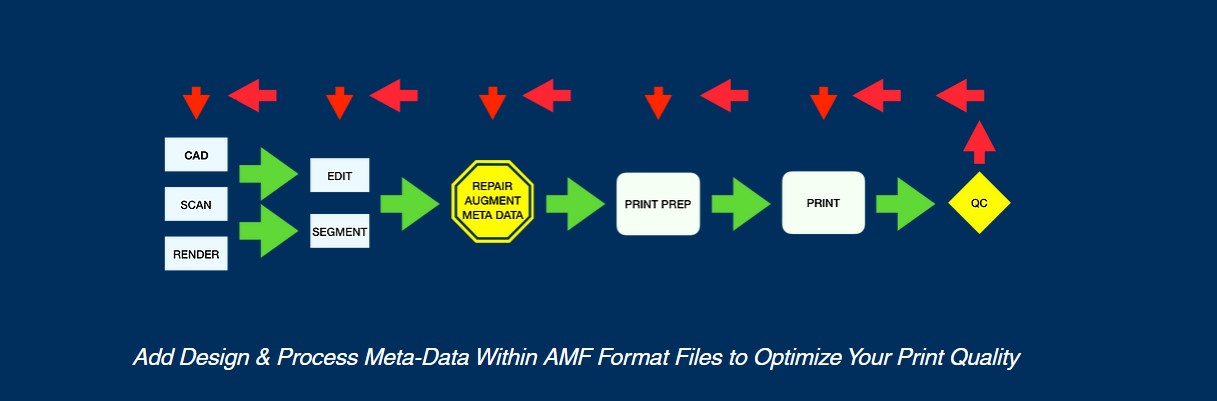

The ability to include all design and workflow-related metadata needed to verify the printed device meets the intended accuracy, precision, and quality within the file, provides a reliable method to programmatically validate and verify quality. Such an integrated approach can significantly reduce the potential legal liability for AM medical device manufacturers while reducing quality assurance costs. Defense agencies and aerospace regulators have similar requirements, as well as policies for including or linking legacy format documentation to the 3D file. ISO/ASTM 52818 provides more detailed technical guidance on this topic.

Finally, some government agencies and commercial companies have policies favoring products produced using international standards-based technology. ISO and ASTM are the two key global standards organizations publishing AM-specific standards, such as ISO/ASTM 52915, which defines the specification for the AMF format(“additive manufacturing format”).

- According to you, does STL remain one of the most widely used formats because it is widely known?

From my perspective, STL continues to be widely used because of its ease of adoption, minimal cost, perception of low legal risk and broad support by conventional software and printing systems. There is also a great deal of inertia in the industry, and frankly, lack of understanding of the benefits of adopting more advanced formats.

There is a general perception that the risk and cost of upgrading to an advanced format like AMF or 3MF may not be justified. There is a need for industry education on the technical, legal, quality and efficiency benefits these formats provide. While I believe STL will continue to be used broadly for many years, a growing number of manufacturers will be compelled to take the leap to AMF or 3MF as regulatory requirements increase the economic and risk management advantages of upgrading. In the long run, higher quality and workflow efficiency resulting from the use of advanced formats will motivate more manufacturers to migrate to one or both of these formats.

- What are the key advantages and limitations of AMF and 3MF?

Both formats are robust, advanced formats based on XML that contain a myriad of useful features that STL lacks. They are both extensible. Version 1.0 of the ISO/ASTM standard for AMF was initially published in 2014 and has been updated twice. It was the original international standard additive manufacturing format. A few years later the 3MF Consortium was formed to publish and maintain the specification developed by Microsoft. There is significant overlap in the structure and capability of these formats. A few significant differences are as follows:

a. AMF is an international standard jointly published by ISO and ASTM and approved by virtually all member countries. 3MF is a specification published by the 3MF Consortium and controlled by a small number of major companies. ISO standard specifications provide manufacturers an advantage in some government regulated industries, such as medical, defense and aerospace.

b. The 3MF consortium has done an effective job actively promoting its format and educating leading AM systems companies and manufacturers. ISO and ASTM are restricted by their policies from doing much evangelization. They rely on individual companies to fund and implement market education and support, so awareness of the AMF standard and benefits is not as well known.

c. Verson1.2 of the AMF specification includes a broader range of defined meta data tags, as well as optional custom meta data tags that provide a powerful means of incorporating quality, IP, confidential and legacy documentation information within the file. 3MF has a narrower range of defined meta data tags, but the specification includes useful features like 2D thumbnails and digital signatures to validate the file authenticity.

d. Both 3MF and AMF specify use of 3D meshes to define the surfaces of the objects. AMF allows for alternative methods to define the objects, such as constructive solid geometry.

e. Both formats include support for assemblies, but the AMF support is broader. Its “constellations” support provides for any number of discreet objects oriented at specified relationships and orientation with each other.

f. Both formats support the sRGB color model at triangle level up to objects, but AMF allows for optional color models. It also provides for color gradients at triangle level up to objects.

g. Both formats support specification of materials by object, but AMF provides for specifying composite materials and gradient blending of materials by object or component volume.

h. 3MF defines a “package” that includes thumbnails, core properties, digital signatures, custom part, the 3D model with associated object thumbnails(if any), 3D textures(if any) and print tickets. AMF provides for inclusion of additional files integrated with the mesh file in a zip file. AMF includes the “.url” meta data tag that enables users to list a specific web address where additional proprietary or confidential information can be accessed via user-initiated authentication. This can be of unique value in protecting copyrights, and sensitive information, such as military technical data packages with confidential contents.

i. ISO and ASTM provide for a member peer review and democratic voting process on approving new revisions to the standard. With global membership of hundreds of organizations, including academic, research, government agencies and commercial companies, a draft revision is reviewed and critiqued by a large and diverse number of professionals and stakeholders before being approved for publication. My understanding is that the 3MF consortium provides for any member to provide input and critique to draft revisions, but only full dues-paying “Steering Member” companies (18 commercial companies) vote.

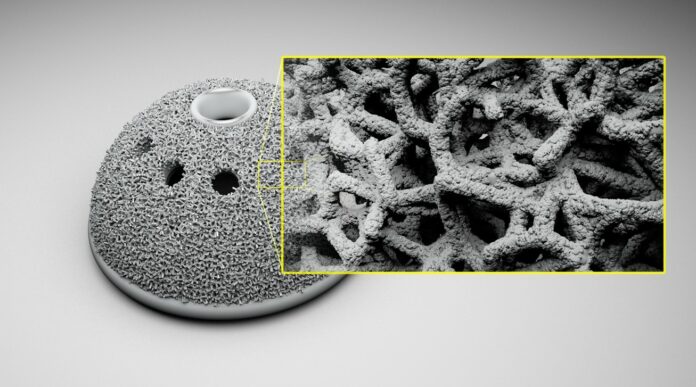

j. The 3MF consortium has published a few optional add-ons to the basic specification. They offer advanced support for lattices. AMF currently lacks any optional add-ons, but ISO TC261 joint committee for additive manufacturing has published a number of technical guidance documents, including ISO 52918 on medical AM applications. Several other ISO standards reference AMF as part of their AM specific specifications, and more industry specific guidance for the AM universe is being developed for future publication.

In summary, both formats have some valuable, advanced features that enable manufacturers to design and build more sophisticated parts using additive manufacturing more efficiently. Both formats will be used by a growing number of manufacturers as the use of AM technology broadens to address a greater number of parts and assemblies around the world.

- Any last words to add?

I encourage readers to learn more about both formats and assess the merits for their specific applications and industry.

On balance, we think the prudent choice for a great number of companies will be to consider the strategic value of employing ISO standard AM specifications, including AMF in their design, production, quality control and quality assurance programs. With 28 published standards on materials, process, design, quality testing, and related topics, and 31 new standards projects in development, most manufacturers will find they will benefit from utilizing these integrated standards to improve the quality and efficiency of their AM activities. With another 30 standards products under development, the ISO standards and technical guidance cover the entire “design to print to post process to quality assurance” workflow (see enclosed ISO/ASTM chart).

Currently, the ISO TC261 technical working group J64 on file formats is seeking input from industry stakeholders for creating industry and application specific technical guidance, including additional meta data fields for improved workflow efficiency. Interested parties can reach out to bobz@avante-technology.com.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.