Simufact, a company of Hexagon, made a real splash at Formnext with the launch of two solutions for additive manufacturing operators. The company aimed at demonstrating tailor-made solutions to improve quality in additive manufacturing processes.

A simulation solution for DED 3D printing

Known for its simulation solutions for metal 3D Printed parts, the software editor has been working on new solutions that would improve quality for Direct Energy Deposition 3D Printing.

As a reminder, DED comprises a range of metal AM technologies that produce parts by melting and fusing material as it is deposited. They include 3D Laser Cladding, Wire Arc Additive Manufacturing (WAAM), Direct Metal Deposition (DMD), or Laser Metal Deposition (LMD).

Such type of technologies enables applications such as the repair of damaged parts and the fabrication of large metal parts that are not possible with Powder-Bed Fusion technology.

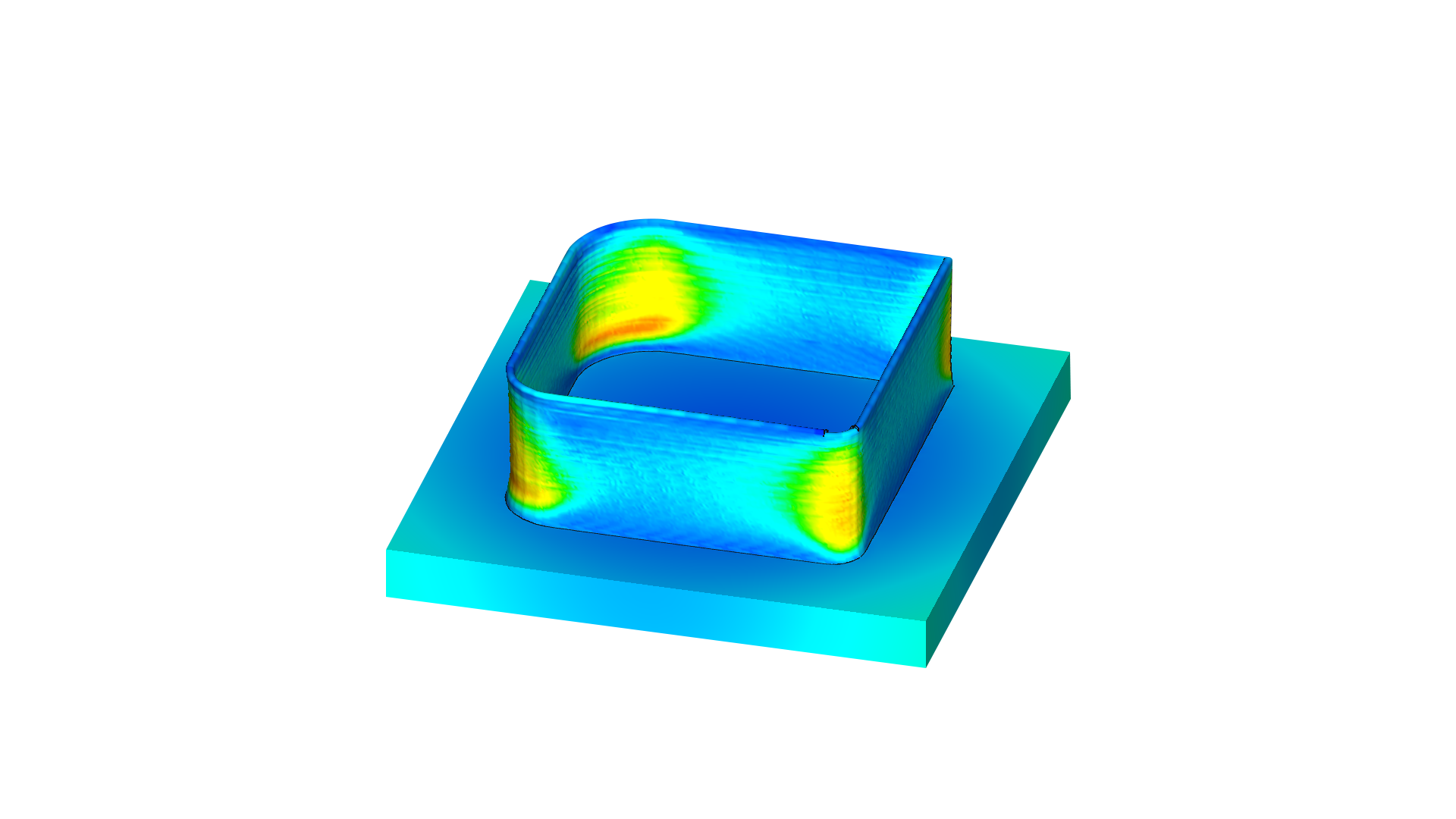

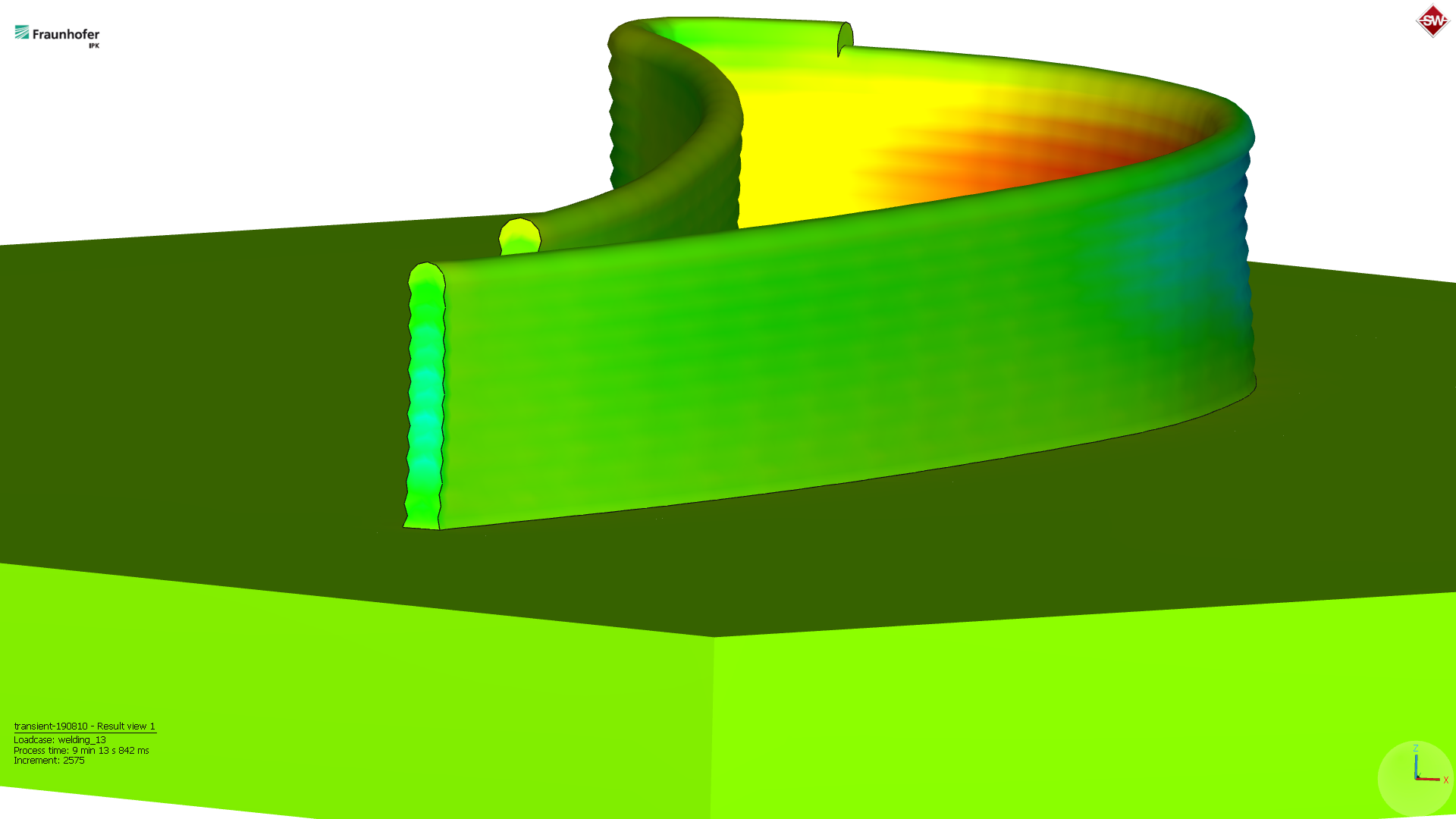

The solution is provided as a module inside the Simufact Welding 2020 software. It enables the engineer to import existing tool paths direct from G-Code instead of defining weld paths manually. With the goal of setting up robust DED simulation models, the new solution enables an easy evaluation of stresses, strains, distortions, thermal history and hot spots during the manufacturing. Furthermore, it is possible to adapt the G-code based on the feature to evaluate.

Once these distortions are identified, it becomes easier to recommend compensations or prevent defects that may occur during the manufacturing process.

Relying on automation to improve quality

Automation of processes has been a key driver for AM specialists that needed to save time by removing manual operations throughout the value chain. In this vein, it should be noted that most of these automation tools are often observed at the software level.

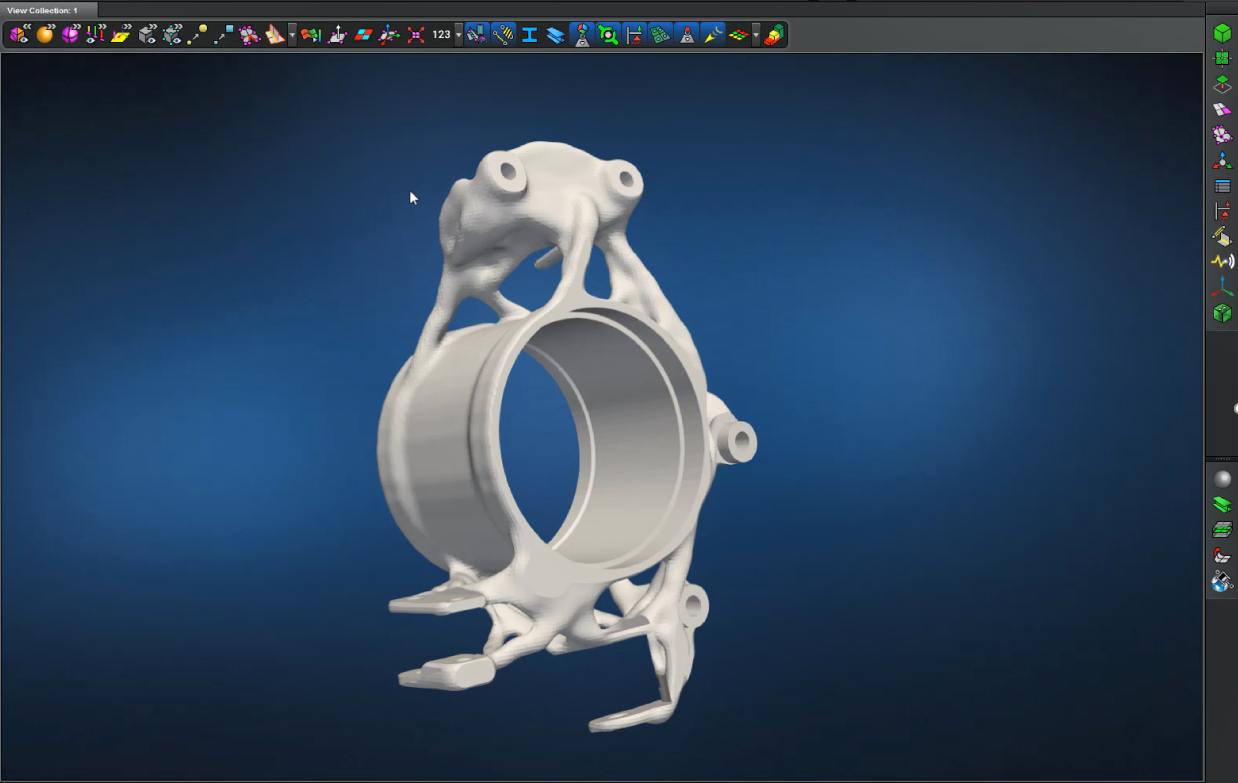

Simufact brings to the market a design optimisation solution that improves quality through automation of design processes with embedded manufacturing knowledge.

Named MSC Apex Generative Design, the new solution is said to improve productivity by up to 80% compared to classic topology optimisation. Simply put, Simufact has re-thought design optimization by enhancing the creative process so that designers have more time to optimise the product’s concept and integrate additional features that add value.

“New design freedoms in additive manufacturing request new-generation software solutions, which take full advantage of the new DfAM possibilities. We make the generative design process smarter by producing design candidates that both satisfy the engineering criteria and look as the designer intended when 3D printed”, said Dr. Thomas Reiher, Director of Generative Design.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com