Home =

LEHVOSS Group - search results

If you're not happy with the results, please do another search

MakerBot adds 3D printing Composites Materials from LEHVOSS Group to its materials portfolio

3D printer manufacturer MakerBot has announced a new addition for its MakerBot LABS: three new LUVOCOM® 3F materials from provider of high-performance thermoplastics LEHVOSS Group.

The new additions bring the number of materials that...

New Consortium Led By LEHVOSS Group Will Explore Overprinting With High-Performance Polymers

Just when you think you've seen everything that can be done with additive manufacturing, a new application, a new project, shows you otherwise. A new consortium formed by University of Exeter (Center for AM),...

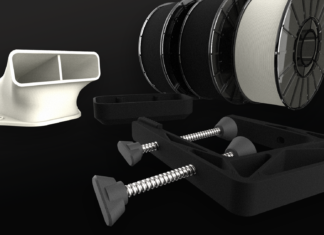

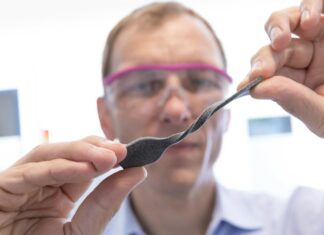

Lehvoss Group on 3D printing material certification, direct fastening of 3D printed parts and next issues to address

“How can I guarantee that if I buy a material, I will have the same reproducibility in twelve years?”

A few years ago, at the heart of the first 3D printing applications developed by sportswear...

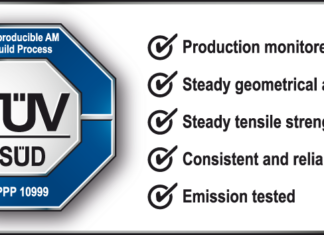

TÜV SÜD certifies Filament and 3D Printing Process from Ultimaker and LEHVOSS Group

TÜV SÜD has certified the 3D printing process of LUVOCOM® 3F filament and Ultimaker S5 Pro Bundle. The LUVOCOM® 3F filament is a high-temperature-based material developed by LEHVOSS Group, which is also a material partner of the...

What could two 3D printing material producers possibly do together? Evonik and LEHVOSS told us.

New partnership will lead to new solutions for the automotive industry

Specialty chemicals company Evonik and chemical and mineral specialties group LEHVOSS Group have announced a partnership to create new material solutions for industrial 3D printing. Being...

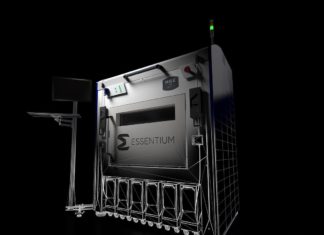

Essentium is working with Lehvoss to develop high-performance 3D printing materials

Essentium & Lehvoss Group are currently collaborating to produce high-performance 3D printing materials.

Essentium is a US-based manufacturer of extrusion-based 3D printing processes. Its 3D printers required high performance materials that can enable the fabrication of...

OPINIONS: What more can we expect from Additive Manufacturing materials?

Wood, pellets, resins, powders, filaments…industries can almost 3D print any form of material and the fascinating processes that enable to transform these materials into finished products are also the ones that make the use...

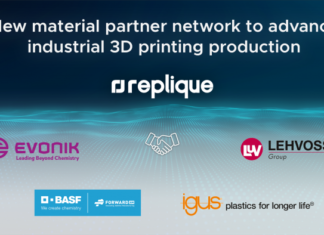

REPLIQUE establishes network of material partners to advance industrial 3D printed production

In this industry, it makes sense to see 3D printer manufacturers or software providers have material producers as key partners but it’s quite unusual to see a developer of a digital distributed manufacturing platform...

Qualification & Certification: Their Differences & Next Challenges for Additive Manufacturing

One usually focuses so much on end-applications that it is easy to forget that what makes an additive manufacturing-based application viable for a given industry, is a pivotal end-to-end qualification and certification process. As...

Essentium says its IDEX-based 280i HT 3D Printer is five to 15x faster than competitive offerings

Essentium is challenging the market of independent dual extrusion system (IDEX) with a new 3D printer: the Essentium High Speed Extrusion (HSETM) 280i HT 3D Printer.

Designed and developed to meet the requests of the...